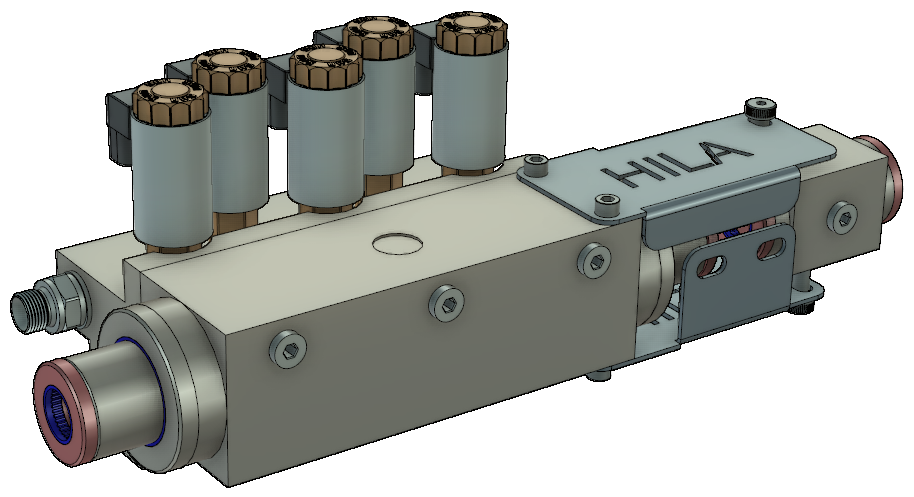

How it works

In short, the actuator is based on two connected short hydraulic cylinders, which are open at both ends, as if every other “climbs” on a fixed clamped piston rod by means of hydraulic clamping connections. In this way, the cylinder can be made to travel along the rod, as when two hands haul in a rope with a load.

It is based on well-known, robust and cost-effective standard components (COTS) for hydraulics. Unique characteristics of the Flexrow actuator are the long strokes, the high system pressure and a compact and light actuator solution. It can be implemented in demanding environments, especially in mobile applications, where there presently are no alternative solutions.

In contrast to ordinary ball screws or rack and pinion, Flexrow actuators also fit in applications used in tough environments, as forests, agriculture and mining. In comparison with conventional long-stroke hydraulic cylinders, Flexrow can offer shorter, more compact and easier-to-place actuator solutions with long strokes.

Another advantage is that the system’s need for hydraulic oil is only a fraction of what an ordinary hydraulic cylinder would require at the same stroke. Since the piston products in the cylinders are symmetrical. There is only marginal variation of the volume of oil in the system during feeding, which leads to minimal leakage of environmentally hazardous hydraulic oil into the vehicle.

Configurations

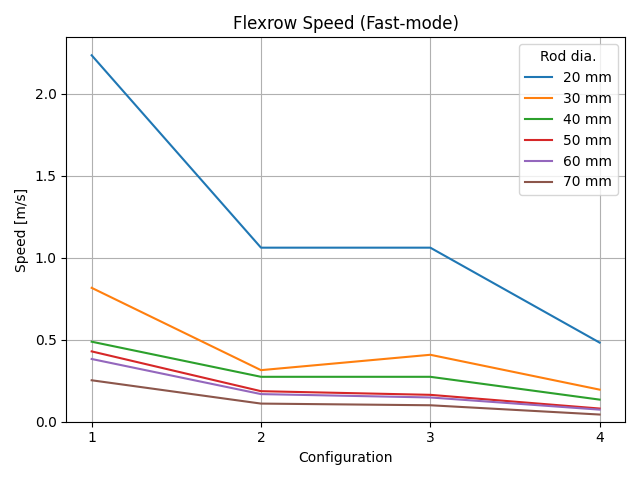

There a four main configurations of the Flexrow cylinder depending on the performance requirements. The configurations are summarized in the list below.

- Std. sleeve

- Std. sleeve w. intensifier

- Spec. sleeve

- Spec. sleeve w. intensifier

Operational modes

Flexrow has two main working modes, “fast mode” and “double-grip” mode. A Flexrow cylinder can switch seamlessly between modes depending on operational requirements.

When working in fast mode the two cylinders are taking turns in engaging with the piston rod and is therefore able to create a continuous motion of the piston rod.

When working in double-grip mode both cylinders are engaged to the piston rod simultaneously. This generates twice the force of fast mode but with the drawback that the motion is stepwise and the total speed is half that of fast-mode.

Performance

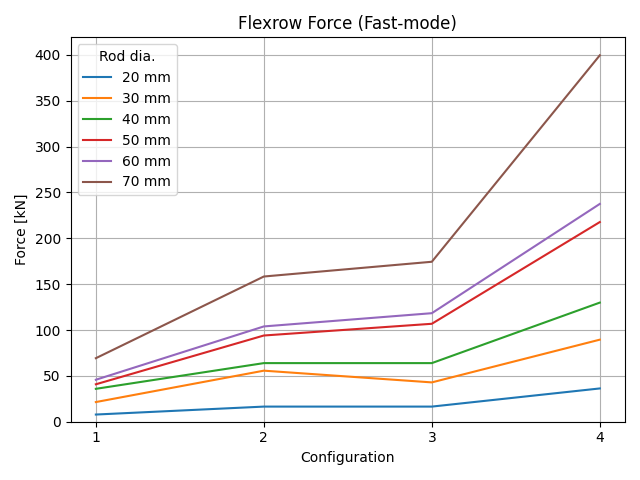

Below is two graphs showing the force and speed for the different sizes and configurations of the Flexrow cylinder when running in fast mode. The operating pressure is 21 MPa and the flow is 50 litre / min.

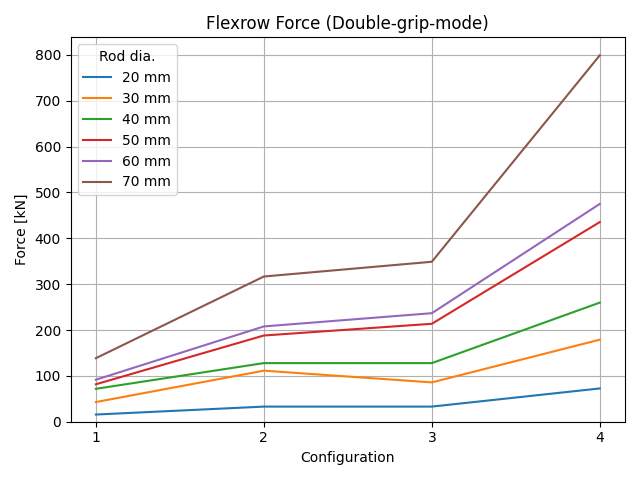

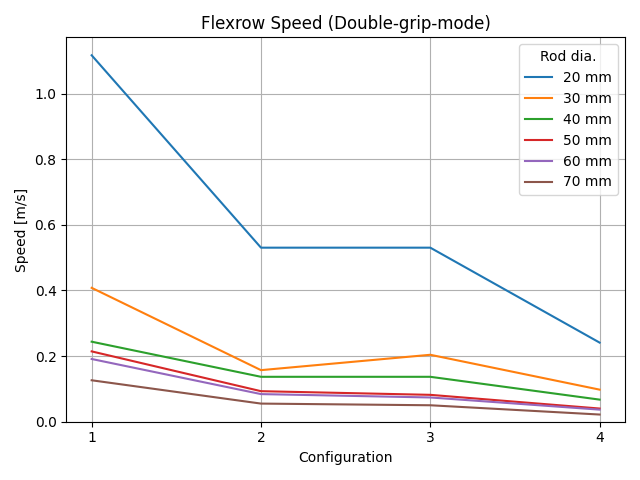

Below is two graphs showing the force and speed for the different sizes and configurations of the Flexrow cylinder when running in double-grip mode. The operating pressure is 21 MPa and the flow is 50 litre / min.